FULL FPGA

Compensate THDv & THDi

Response Time ≤1ms

Resonance Free

FULL FPGA

Compensate THDv & THDi

Response Time ≤1ms

Resonance Free

INTRODUCTION

iKonMac breaks through the barrier of the lack of a complete solution to power quality issues in weak grid environments. The independently developed Ultra AHF series stable active power filters perfectly achieve the goal of jointly controlling current harmonics and voltage harmonics.

The Ultra AHF series stable active power filters feature faster response times and can more accurately avoid resonance. The most prominent advantage is the ability to simultaneously control various unstable harmonics and stabilize the power grid.

Applicable Load Types

Advantages

- Compensate THDi & THDv

- Mitigate All Unstable Harmonics

- Switching frequency 80kHz

- Response time ≤ 1ms

INTRODUCTION

iKonMac breaks through the barrier of the lack of a complete solution to power quality issues in weak grid environments. The independently developed Ultra AHF series stable active power filters perfectly achieve the goal of jointly controlling current harmonics and voltage harmonics.

The Ultra AHF series stable active power filters feature faster response times and can more accurately avoid resonance. The most prominent advantage is the ability to simultaneously control various unstable harmonics and stabilize the power grid.

Applicable Load Types

Advantages

- Compensate THDi & THDv

- Mitigate All Unstable Harmonics

- Switching frequency 80kHz

- Response time ≤ 1ms

APPLICATIONS

Semiconductor Industry

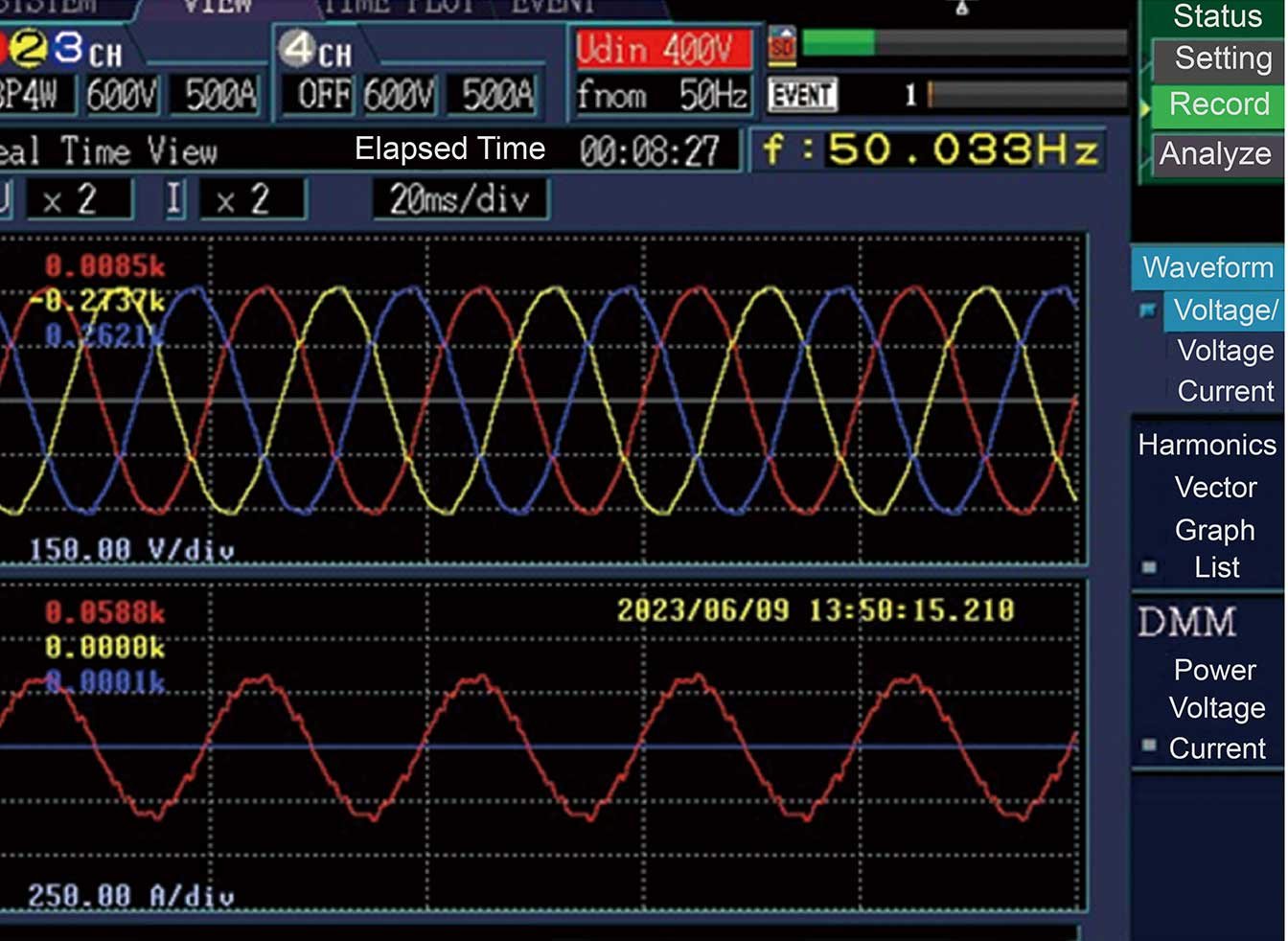

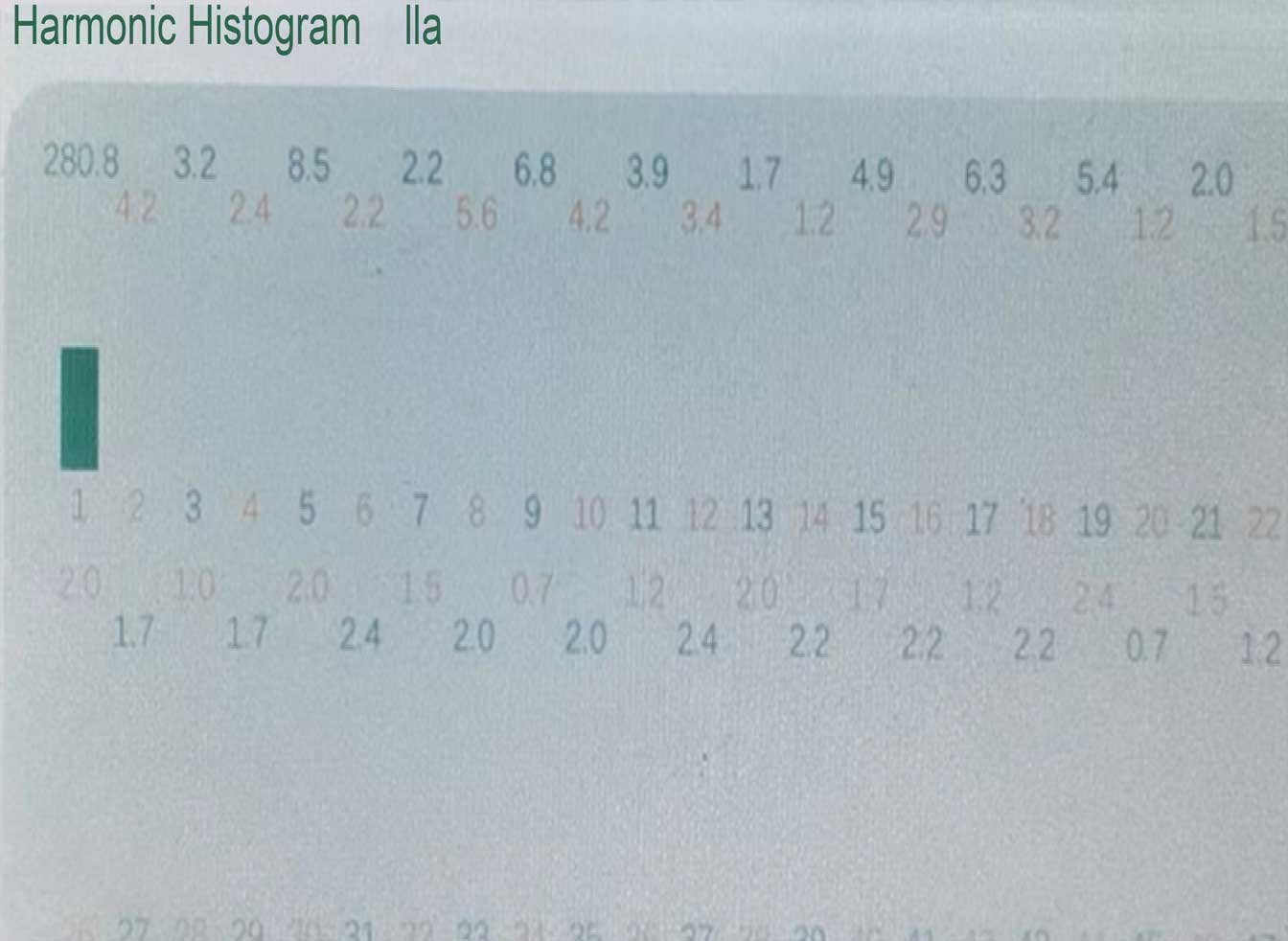

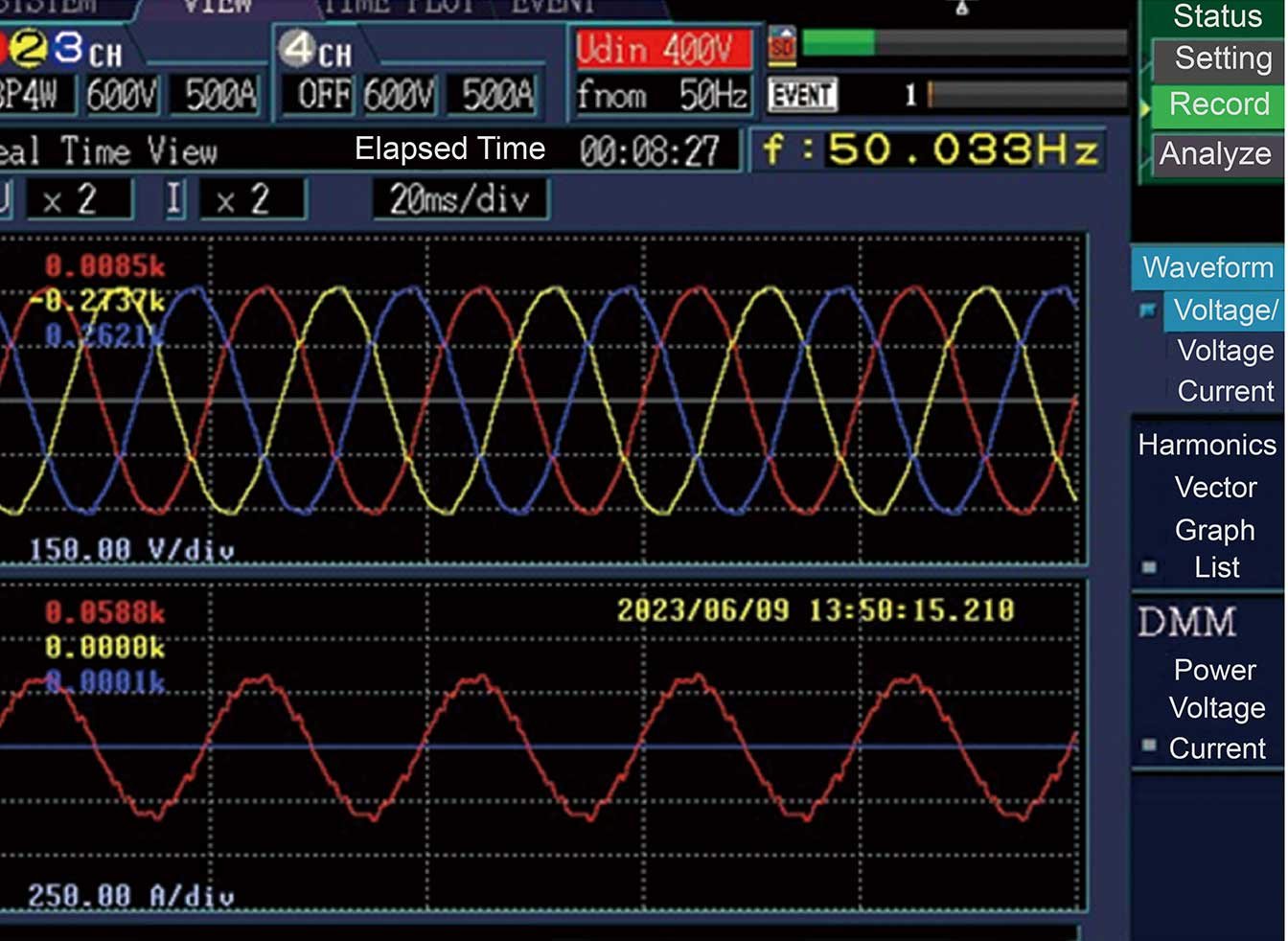

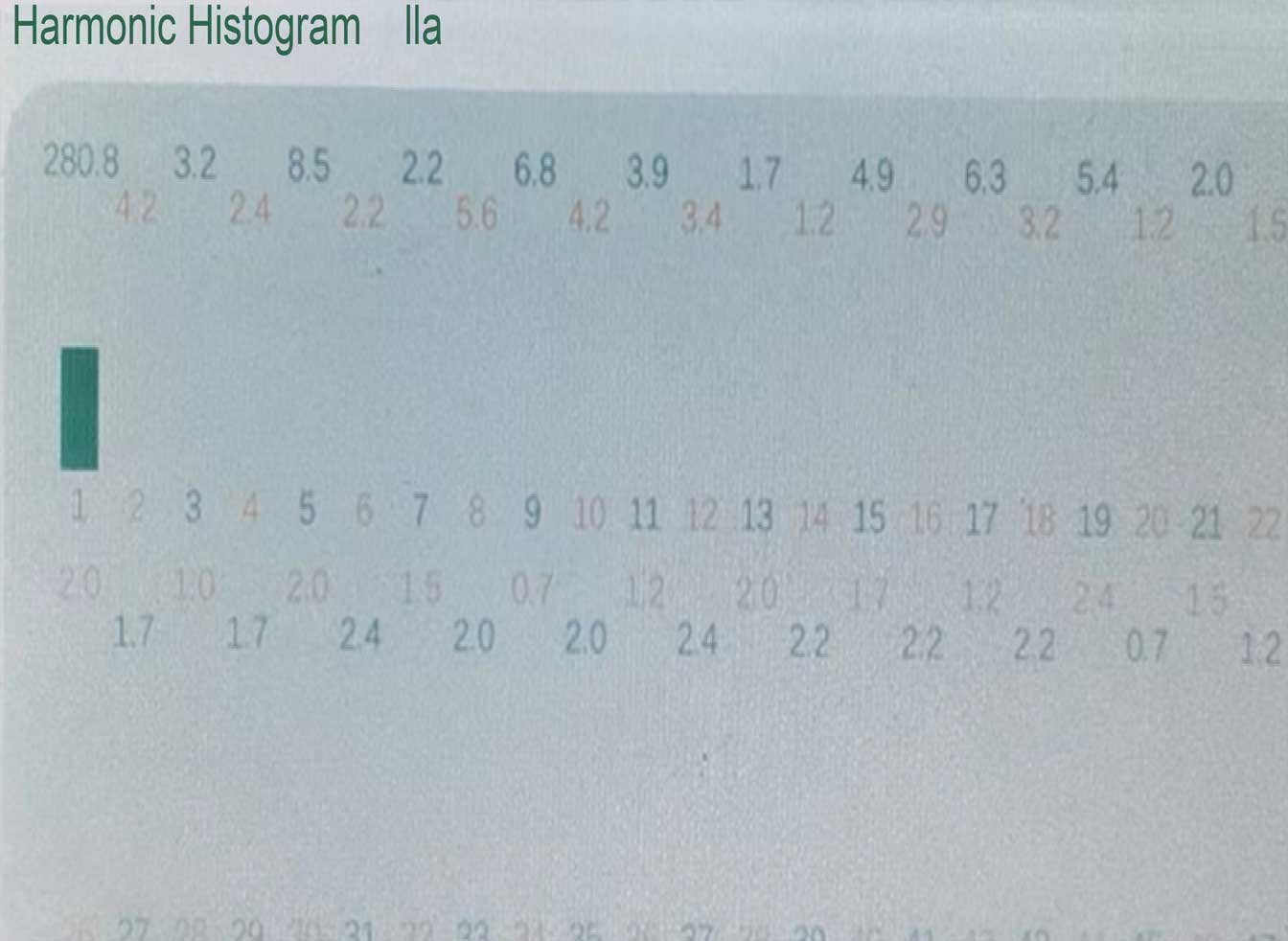

THDv After Mitigation 2.3%

Supress Odd Harmonics

Even & Odd Harmonics Eliminated

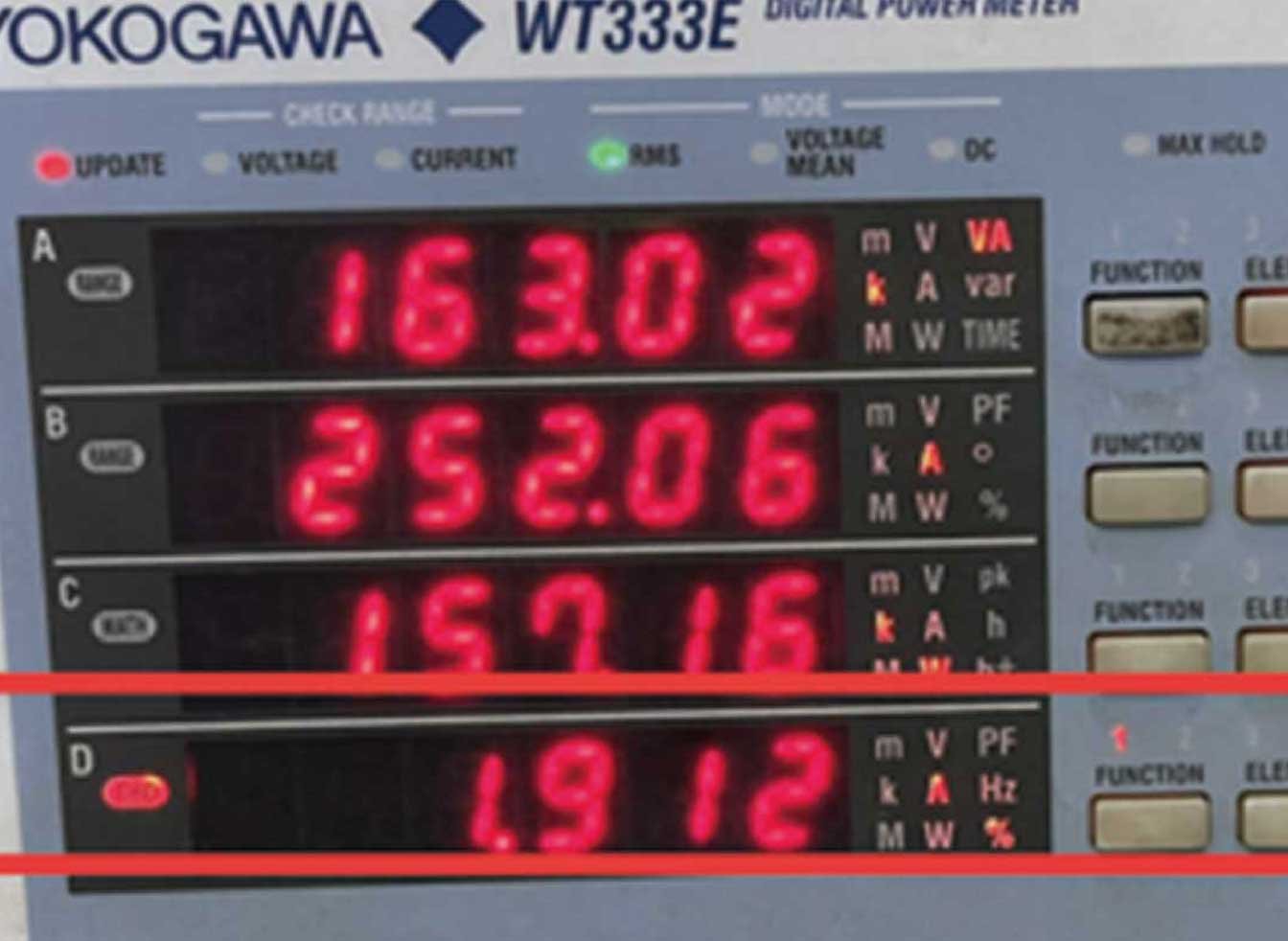

Rectifier Power Supply

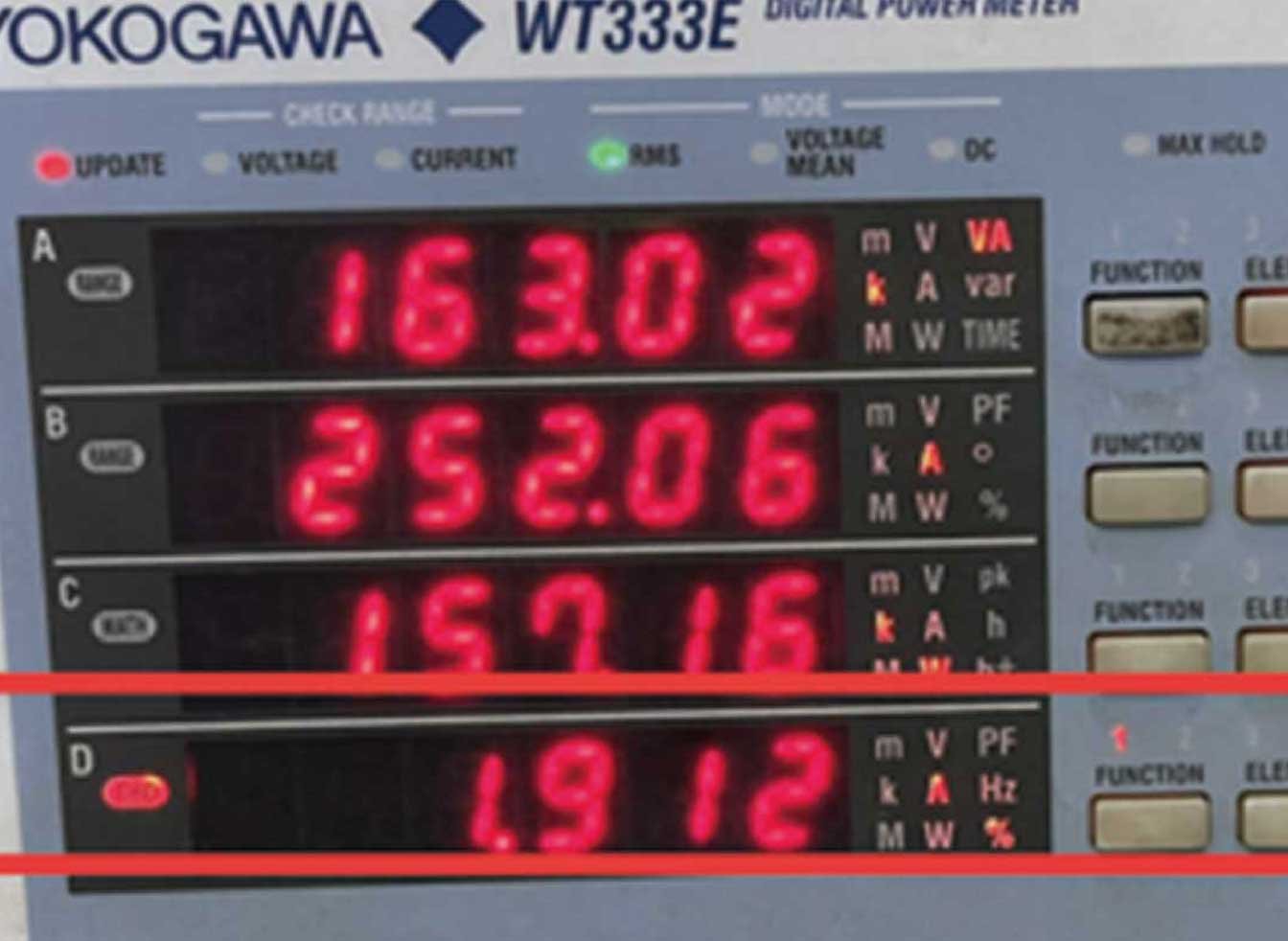

THDi After Mitigation 1.9%

APPLICATIONS

Semiconductor Industry

THDv After Mitigation 2.3%

Supress Odd Harmonics

Even & Odd Harmonics Eliminated

Rectifier Power Supply

THDi After Mitigation 1.9%

PARAMETERS

|

Voltage Level |

304V-456V |

|

Module Capacity |

Active Harmonic Filter: 100A/150A |

|

Module Size (W*H*D) |

680*200*545 |

|

800*800*2200 (Max Capacity Per Cabinet) |

750A |

|

Number of Parallels |

12 |

|

Operating Frequency |

50Hz (-10% ~ +10%) |

|

Current Transformer |

100 : 5 ~ 10000 : 5 |

|

Controller |

100% Full FPGA, 16 CPUs parallel computation |

|

Compensate For Harmonics |

2-50th Order Harmonics |

|

Efficiency |

>98% & THDi <5% |

|

Switching Frequency |

80kHz (7th Generation Infineon IGBT) |

|

Methods of Communication |

RS485, Modbus RTU, Wifi (Remote control) |

|

Upper Level Software |

Yes, all parameters can be set by the upper-level software |

|

Fault Alarm |

Yes, up to 500 alarm messages can be recorded |

|

Monitor |

4.3" / 7" / 10" / 12" (Optional) Support independent monitoring of each module / centralized monitoring of the whole machine |

|

Full Response Time |

≤1ms , instant response ≤50us |

|

Active Loss |

≤2% |

|

Heat Dissipation |

Intelligent air cooling |

|

Noise |

≤60dB |

|

Protection Features |

There are more than 20 kinds of protection such as overvoltage, undervoltage, overheating, overcurrent, short circuit, etc |

|

CT Installation Location |

Load side |

|

Module Weight |

38.5kg |

|

Operating Temperature |

-20°C ~ +55°C |

|

Elevation |

<5000 meters (More than 1000 meters, for every 100 meters of additional elevation, the power is reduced by 1%) |

|

Relative Humidity |

<95%, No condensation |

|

Ingress Protection |

Module IP20 + Electronic Layer IP42 (Customizable IP54 or IP65) |

|

Pollution Resistance Rating |

Level 2 (Customizable Level 3) |

PARAMETERS

|

Voltage Level |

304V-456V |

|

Module Capacity |

Active Harmonic Filter: 100A/150A |

|

Module Size (W*H*D) |

680*200*545 |

|

800*800*2200 (Max Capacity Per Cabinet) |

750A |

|

Number of Parallels |

12 |

|

Operating Frequency |

50Hz (-10% ~ +10%) |

|

Current Transformer |

100 : 5 ~ 10000 : 5 |

|

Controller |

100% Full FPGA, 16 CPUs parallel computation |

|

Compensate For Harmonics |

2-50th Order Harmonics |

|

Efficiency |

>98% & THDi <5% |

|

Switching Frequency |

80kHz (7th Generation Infineon IGBT) |

|

Methods of Communication |

RS485, Modbus RTU, Wifi (Remote control) |

|

Upper Level Software |

Yes, all parameters can be set by the upper-level software |

|

Fault Alarm |

Yes, up to 500 alarm messages can be recorded |

|

Monitor |

4.3" / 7" / 10" / 12" (Optional) Support independent monitoring of each module / centralized monitoring of the whole machine |

|

Full Response Time |

≤1ms , instant response ≤50us |

|

Active Loss |

≤2% |

|

Heat Dissipation |

Intelligent air cooling |

|

Noise |

≤60dB |

|

Protection Features |

There are more than 20 kinds of protection such as overvoltage, undervoltage, overheating, overcurrent, short circuit, etc |

|

CT Installation Location |

Load side |

|

Module Weight |

38.5kg |

|

Operating Temperature |

-20°C ~ +55°C |

|

Elevation |

<5000 meters (More than 1000 meters, for every 100 meters of additional elevation, the power is reduced by 1%) |

|

Relative Humidity |

<95%, No condensation |

|

Ingress Protection |

Module IP20 + Electronic Layer IP42 (Customizable IP54 or IP65) |

|

Pollution Resistance Rating |

Level 2 (Customizable Level 3) |

QUALITY CONTROL

IGBT Module Assembly

Automatic Soldering

Inductance Soldering

Assembly

Low-Voltage Testing

High-Voltage Testing

Aging Test

Final Inspection

Packaging

QUALITY CONTROL

IGBT Module Assembly

Automatic Soldering

Inductance Soldering

Assembly

Low-Voltage Testing

High-Voltage Testing

Aging Test

Final Inspection

Packaging